Enhanced Safety in High-Torque Applications: HEICO-LOCK® Reaction Washers

Secure large bolted joints without reaction arms and protect them against self-loosening – The innovative HEICO-LOCK® Reaction Washers deliver reliable connections and reduce the risk of accidents when using high-torque tools.

Tightening large bolted joints is often a challenging and time-consuming process, yet such heavy-duty fastenings are commonplace in wind turbines, the oil & gas industry, hydroelectric power plants, as well as on pumps and pipelines. From nominal size M24 upward, the required torque exceeds what can be applied by hand, so electrically, hydraulically or pneumatically driven torque tools are normally employed.

Increasingly, high-torque tools are used even on smaller sizes (e.g. M16), especially in series production. When many identical bolts are tightened, investing in an appropriate torque tool quickly pays off - even at M16. Traditionally, such tools require a reaction arm to absorb and redirect the reaction torque into surrounding structures, ostensibly to stabilize the joint during tightening. Yet despite reaction arms and additional supports, serious accidents still occur: fingers can be pinched or crushed, and tool slip-offs can cause injury, even for experienced professionals.

“Safety was our clear priority in developing the HEICO-LOCK® Reaction Washers,” explains Sven Heggemann, bolting specialist in technical sales at the HEICO Group, whose expertise shaped the product’s design. “We set out to create an efficient locking solution compatible with virtually all major torque-tool brands - eliminating the need for reaction arms or external supports.”

Like all HEICO-LOCK® bolt locking systems, the Reaction Washers employ a two-piece, wedge-lock principle proven to prevent self-loosening under vibration and dynamic loads. Special HEICO dual sockets make the washers compatible with almost every well-known torque-tool manufacturer, so users can continue using their existing equipment. The tool’s reaction torque is introduced through the dual socket into the gear-shaped outer contour of the reaction washer, which both transmits and supports the load. Consequently, torque is applied purely axially - without bending moments -enhancing tightening accuracy and extending tool life.

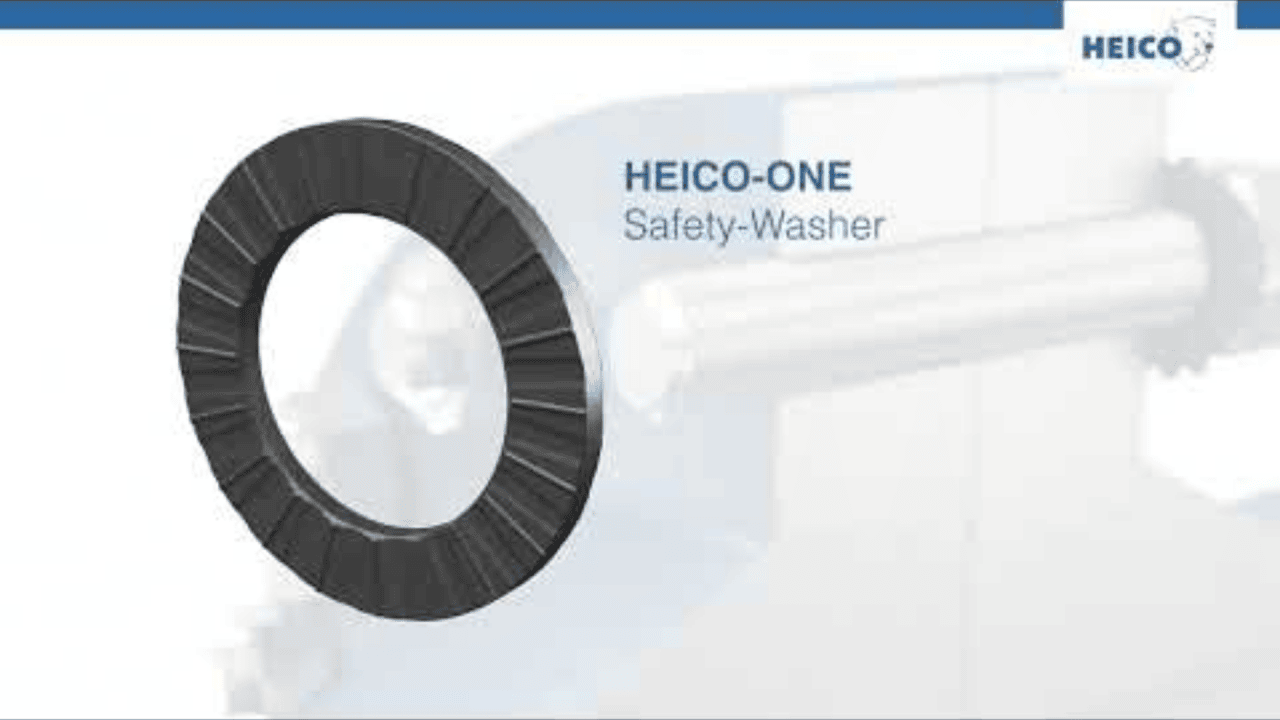

For through-bolt assemblies where no counterholder can be used, the HEICO Group has introduced the HEICO-ONE Safety Washer. Its wave-shaped serrations on both sides embed into the mating material or the nut/bolt head, immediately and effectively preventing the passive side from turning during tightening. This makes the HEICO-ONE Safety Washer the perfect complement in through-hole applications.

With safer and faster handling of high-torque assemblies, efficient bolt security and broad compatibility with nearly all major torque tools, HEICO-LOCK® sets new standards in bolting technology.